FES

Using cutting-edge technologies Make your factory smarter and more efficient

The broad portfolio of equipment & solutions for freezing and food processing.

We drive for more value for our customers.

Using cutting-edge technologies Make your factory smarter and more efficient

Through fluidization IQF-technique, high velocity cold air jets blast upwards through densely arrange tapered holes to form four directional freezing zone. Food products enter freezing zone at an elevated level, "float" through the freezing zone. Air circulation is guided naturally for uniform exposure to achieve both ultimate production cycle and superior IQF results. Intensity of circulation airflow continuously varies to generate true fluidization in accordance with product categories and weights.

Through dynamic air and drive innovation, food products enter and float through aerodynamic zone, and come out with superior natural appearance.

Through true fluidization and proper freezing sequence, even most troublesome products can be individually quick frozen. Traditional vegetables like green peas, diced or sliced root vegetables, diced fruit, whole or sliced berries. Light weight products like leafy, herbs, rice and pasta. Protein products like shredded, minced or diced meat, diced poultry, shrimps, mussels and cheese also can be perfectly frozen with the I.Q.F-technique that meets the toughest requirements for hygiene, yield and economy.

Controlled movement of conveyor belt, variable control of all fans, continuous and gentle separation of product particles, independently adjustable Dynamic Turbo Airflow to form four-dimensional air zone for highly efficiency heat transfer and premium IQF freezing.

PULSATION, AIR BYPASS, TRACK AIGTATION, AIR MODULATOR

For delicate products. The surface frozen of food products will be achieved in the first zone and products are completely separated through belt move and airflow dynamic control, while the crust-frozen products is deeply frozen in the second zone.

Unparalleled flexibility in production, suited for a wide range of products, from basic and traditional to wet and sticky, particularly suited for the delicate, fragile products.

Specially designed low-noise emission radial fans which are located at downstream side of the evaporator circulation airflow, minimize snow build-up, which are unaffected by pressure variations, maximizes airflow efficiency, profitable uptime and running reliability

Normally frost and snow easily accumulates on evaporators while freezer is in the mode of production. ADF Air Defroster greatly increases coil heat transfer efficiency, improves productivity and reduces power consumption, maintains constant temperature and airflow during the entire production run by continuously eliminating frost and snow build-up on freezer coil during production period, as the air flow is not obstructed by frost. ADF significantly extends operating hours between water defrosts.

The evaporator reinforced fins with variable and staggered spacing gives minimum air pressure drop and maximum uptime between defrosts, customized design for specific refrigeration to ensure highly efficient heat transfer. Designed for hot gas, water and/or ADF Air Defroster.

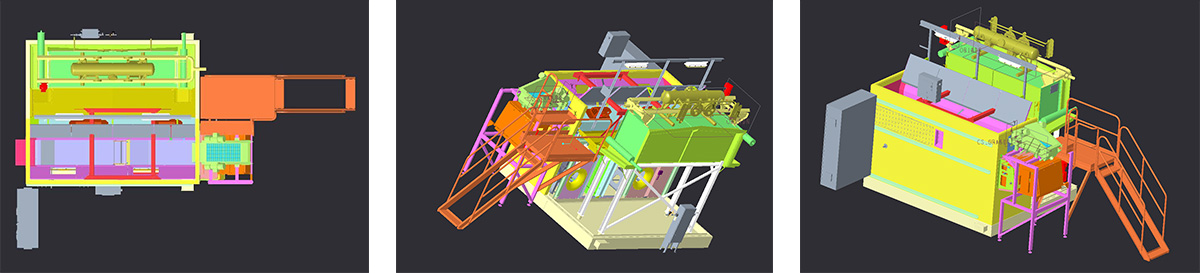

Fully seal welded stainless-steel construction, with elevated floor-wall joint, supplied in pre-fabricated modules. Drains are located in the corners of the sloped floor modules, for easy cleaning, complete drainage and superior hygiene.

State-of-the-art modular design, uncompromising quality pre-assembly and site installation, low freezer base load and high utilization of refrigeration.

Stainless steel surfaces and accessible areas

Sequential Hot Gas Defrosting allows in excess of 6 days continuous production.

Less than 2 hours downtime with steam injection or hot gas/water defrost.

Automated infeed shaker for even distribution or high de-watering capabilites.

Belt Strack Online Rinser cleans the first belt and removes product debris without raising freezer temperature, improves hygiene and extend production run between defrosts.

Customized feeding conveyor and sloped chute outfeed for sensitive products.

Fully seal welded stainless steel insulation housing, improves hygiene.

Customized enclosure size, frost trap design for ultimate uptime.

PRODUCTION CAPACITIES: From 1,000kg/hour to in excess of 5,000kg/hour, capacity increments 1,000kg/hour.

REMARK: Capacity based on green peas, ammonia -40oC evaporation temperature, 15℃infeed temperature.

Guideline only, for more details contact FES Technologies.